With more emphasis being placed on sustainability and the circular economy, especially in construction, Fairview is taking a proactive approach to enhance sustainability in the industry through the introduction of Ecoloop. Ashley How leads the Fairview Innovation team and explains the Ecoloop initiative as well its significance environmentally.

The construction industry contributes to almost all types of pollution and is responsible for more than 30% of the extraction of natural resources, as well as 25% of solid waste generated in the world.

The Ecoloop initiative was established in response to state governments’ mandated removal of polyethylene (PE) cladding, as part of comprehensive rectification initiatives across the country. A growing number of modern buildings utilise cladding made up of composite panels, such as aluminium composite panels (ACP). These are generally two thin sheets of aluminium separated by a core material. The core can be made up of PE, mineral fibre or a combination of both, and can contribute to how easily the cladding burns and its potential to spread fire.

In NSW, ACP, with a core comprised of more than 30% PE by mass has been banned from any multi-storey use. In response to the Grenfell Tower fire tragedy in London in 2017, an inter-agency Fire Safety and External Wall Cladding Taskforce was created to ensure that fire safety for residential buildings are prioritised and properly addressed. This has seen many cladding rectifications made to buildings across Australia.

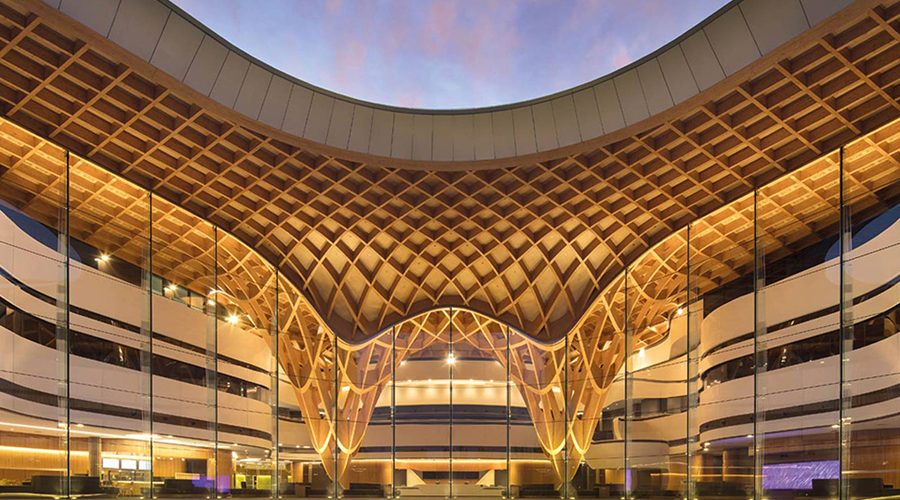

Perth Stadium

What is Ecoloop?

Ecoloop is Australia’s first ACP recycling solution for recladding waste, designed by Fairview in collaboration with waste management expert, Eco-Smart after undertaking extensive research and trials. Unlike any other recycling program in the market, Ecoloop is recycled here in Australia, creating employment opportunities for Australians, and providing an Australian solution following Australian Standards.

Identifying a gap within the market, Ecoloop sees ‘non-compliant cladding’ waste from rectification projects recycled and repurposed, diverting up to 100% of non-compliant ACP cladding material from landfill. As it stands, construction waste is either sent to landfill or sold for scrap metal. However, scrap metal yards also struggle with excess material, meaning their waste often gets sent to Australian landfill or exported to developing nations. This is not an ethical or sustainable option and the Australian Government is tightening export policies.

The expert Ecosmart team has more than 30 years’ experience in construction waste management, achieving over 97% sustainability outcomes, and has is the first and only construction waste company to achieve GECA/End of Life Cycle Global Certification.

Industry-wide sustainability is at the heart of this initiative, meaning Ecoloop has been designed as an easy choice and process for builders, building owners, councils, developers, owner corporations and strata managers to take the sustainable path with problem cladding, while also facilitating the repurposing of new products, reducing virgin material consumption and contributing to the circular economy.

The impact

With an estimated 4.2 million square metres of cladding across Australia identified to require replacement, in environmental terms, this translates to 20,000 tonnes of ACP, which has consumed 340,000 tonnes of greenhouse gases in production and use.

This is more than just a ‘cladding crisis’, it is an environmental crisis.

To explain the significance environmentally, recycling aluminium composite panel offsets virgin material production of aluminium and polyethylene. Repurposing these products consumes less than 20% of the energy required to create the virgin material, which means every m2 recycled has an equivalent reduction in greenhouse gas emissions as planting one tree. That is, 4.2 million m2 of cladding equates to planting 4.2 million trees*

Ecoloop is Australia’s first ACP recycling solution for recladding waste (image: Bunjil Place)

Ecoloop’s capabilities and offerings include:

- Zero % material landfill

- Zero % material exported

- 100% recycled in Australia, following Australian standards and employing Australian workers

- 100% repurposed aluminium products

- 100% repurposed polyethylene products

- End of lifecycle analysis

The take back program and process

If you are aware of a rectification project that requires a reclad solution, Fairview can offer a cladding solution, alongside the Ecoloop service, to recycle the non-compliant cladding that is being removed. The backload service means there are no additional trucks on the road to collect problem cladding.

From January 11, 2021, Fairview’s Ecoloop initiative will commence the collection of cladding waste from rectification project sites before transporting the waste to Ecoloop’s processing facility, where a unique and sustainable separation process is performed.

The panels will be separated into aluminium and PE, and then proceed to different facilities to repurpose the components into other sustainable products such as aluminium building products, park benches, plastic pallets and bottles.

The construction industry contributes to almost all types of pollution and is responsible for more than 30% of the extraction of natural resources, as well as 25% of solid waste generated in the world

Particular concern has been raised as to the polyethylene material and how this can sustainably be reused. The proprietary Ecoloop separation process ensures the PE can be safely and efficiently used in other construction and building products, such as piping and seating. Fairview continues to work with leading Australian universities to explore non-traditional markets for sustainable products.

As with all recycling processes, there will invariably be some waste that does not fall clearly into the aluminium and polyethylene categories, such as paint and sealants. Uniquely, the Ecoloop solution can also prevent this resource going to landfill through Process Engineered Fuels, ensuring it acts as a coal offset.

Where other recycling practices see waste materials shipped overseas for processing, often using harmful and unethical practices, Ecoloop provides an Australian solution, following Australian Standards and employing Australian workers. It is the proactive approach to enhancing sustainability in the construction industry.

Outcomes

An important part of the process is reporting on where the materials end up and their end use. Possible uses and innovative applications for the recycled material, continue to be investigated through our engagement with leading universities and research and technology organisations.

In addition, optional reporting and independent auditing will provide our clients with statistics on how Ecoloop has helped them lessen their environmental impact now and into the future.

How can you play your part?

Rethink rectification and cladding waste. By taking the first step to consider where your cladding waste is going, you are demonstrating environmental awareness.

By contacting Fairview at ecoloop@fv.com.au or visiting www.fv.com.au/ecoloop, you’re showing your commitment to enhancing sustainability in the construction industry.

*Disclaimer: estimates only.